Our key terms for confused customers…

Here at ropelocker, we use many key words and phrases that you might be unfamiliar with. It can be confusing working out what you need to order when you don’t know what splicing, whipping, and tonnes of other words we’re throwing at you actually mean.

We want to help our customers and make buying from us as easy as possible. So, with that in mind, here are some key terms we use at ropelocker that cause the most head scratching and shoulder shrugging among our customers…

ROPE TYPES

SYNTHETIC ROPE

- plastic-based rope

- most of our ropes are synthetic

- some are polypropylene, such as hardy hemp (shown in image)

- others are polyester, such as 3 strand polyester or shockcord, which has a polyester cover

- some are nylon, like multiplait

- and many more!

- synthetic ropes are generally stronger and longer lasting than natural products

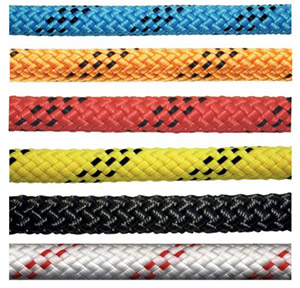

BRAIDED ROPE

- made from many strands tightly intertwined to make a tubular structure

- examples include braid on braid (BOB), dyneema cruise, or silverline (shown in image)

3 STRAND ROPE

- made from 3 separate strands which are twisted around each other to create a length of rope

- examples include hardy hemp, manila, and 3 strand polyester (shown in image)

DOUBLE BRAID

- Some ropes are hollow inside and others are double braided

- double braid essentially means a rope with 2 layers – a cover and an inner core

- also known as braid on braid

- examples include braid on braid (BOB) and Marlow doublebraid (shown in image)

- Rope with elasticity

- will stretch when pulled or loaded (some more than others)

- used for things like climbing, as dynamic ropes will stretch to absorb the shock of a falling climber

- browse our dynamic ropes and look at their descriptions to find details such as their elongation, impact force etc.

- but if you’re stuck, just contact us!

STATIC ROPE

- opposite to a dynamic rope

- won’t stretch

- example would be LSK rope (shown in image) or one of our pre-stretched ropes, such as pre-stretched polyester

- Dyneema is the strongest fibre known to man

- its strength doesn’t relate to rope’s thickness (you can cut through most Dyneema with a decent pair of scissors) but rather its breakload

- for example, Dyneema is used in helicopter winch lines because it’s strong enough to lift tonnes of weight without breaking

- very versatile – used in sailing, recovery vehicles, rigging and more

- we stock a wide range of Dyneema products – take a look at them all here

- some ropes are purely braided from Dyneema, others are combined with other materials

- For example, Marlow D2 Racing rope has a 12-strand Dyneema core combined with a 32 plait polyester cover

- Dyneema is often confused with HMPE – both are pretty much the same, Dyneema is just a brand name

ROPE ADDITIONS/FINISHES

SEALED ENDS

- synthetic ropes are cut with a hot knife at ropelocker to seal the ends

- unable to do with natural fibre rope – will burn!

- creates neat end with no fraying

- cannot be done to heat resistant ropes e.g. Marlow Excel R8

HEATSHRINK

- Added to rope to protect ends

- creates a grippy handle – good for things like gym ropes

- can add heatshrink to your order by customising it before adding to your basket

- can also buy heatshrink seperately

WHIPPING

- Helps to hold the rope together – especially on natural rope which can’t be sealed with a hot knife

- makes rope ends look more neat

- add whipping to your order by customising it before adding to your basket

- we also stock minispools of whipping twine and balls of marline (which has been used to whip ends in image)

SPLICING

- splicing is when a permanent loop (known as an eye) is created in the end of your rope

- good for attaching things e.g you might splice an eye into your decking rope so it can be fixed to some fencing

SOFT EYE

- soft eyes can be spliced into a range of ropes (dyneema cruise rope shown in image)

- soft eyes involve the rope being fed back into itself to create a loop

- many uses e.g handles on dog leads, boat rope etc.

- if you’d like to add a soft eye to your rope customise your order before adding it to your basket

HARD EYE

- involves splicing the rope and holding the eye in place with a thimble

- hard eyes are more rigid than soft eyes

- thimble can help protect the eye from chaffing

- we have different thimbles available at ropelocker – stainless steel, galvanised or nylon (stainless steel shown in image).

- customise your order and add a hard eye to your rope if you’d like us to splice one on for you, or you can buy the thimbles separately

BACKSPLICE

- Involves weaving the end of the rope back on itself

- stops ends fraying

- can only be done in 3 strand rope e.g. manila or hardy hemp (shown in image)

TAPERING

- Tapering is a method of reducing the thickness of a rope

- can be done by trimming the rope’s core or removing the rope’s cover

- creates a thinner, lighter product with less friction

- popular for things like sailing – tapering at the clew, for example, will allow the spinnaker to fly higher

EQUIPMENT AND TOOLS

REEL

- long lengths of rope are often wound onto a reel

- reduces tangling

- easier to transport

- also known as a spool

- we sell rope by the metre at ropelocker, but it’s also possible to buy our products in bulk – take a look at our reel deals for discounted prices!

- Tool used for splicing ropes

- we stock a range of fid types in a variety of sizes

- generally swedish fids (shown in image) are used on 3 strand ropes and selma fids are used on doublebraid ropes

- If you’re working with dyneema, marlowbraid, and other 3 strand core ropes you’ll probably need a splicing needle

- Feel free to contact us for any further advice and splicing guidance

OTHER COMMON TERMS

DIAMETER

- Thickness of the rope (its width)

- we measure diameter at ropelocker in millimetres

- some of our customers get a little confused between inches and millimetres – 1 inch is the same as about 25mm.

HANK

- how we store shorter lengths of rope

- keeps them tangle free

- if you’re looking for range of short lengths of rope at a decent price, you might be interested in one of our hank boxes

BREAK LOAD

- how much stress the rope can handle under tension before it breaks

- you can check a product’s break load in its description on our website

- or contact us if you’re unsure!

ABRASION RESISTANCE

- this refers to how well a rope handles friction, chafing and contact with other objects

- a rope with good abrasion resistance can put up with a lot of friction without becoming damaged

- things can be added to rope to improve its abrasion resistance e.g. chafe guards (see in image)

If there’s anything else you’re unsure about, don’t hesitate to contact us here at ropelocker. We will happily talk you through any rope-related confusion in basic terms.